How to do the daily maintenance of fiber laser cutting machine bed?

- Fiber laser cutting machine guide rail and worktable cleaning and maintenance

- A. How to clean the guide rail?

The rack and guide rail of fiber laser cutting machine should be cleaned regularly. First, remove the stains on the guide rail. After the material is crushed, add a little cleaning lubricant on the guide rail, move the guide rail, so that the clean lubricant is evenly distributed on the guide rail. Be careful not to use lube (butter). The lubricating oil attached to the guide rail is easy to cause the adhesion of the dust causing the deformation of processing material, thus damaging the slider and guide rail.

B.How to clear the working table?

Clean the residual materials processed on the working table of fiber laser cutter. The crawler table needs to use a little clean anti-rust oil for anti-rust treatment every six months.Other tables do not need. Note: the working platform of fiber laser cutting machine cannot be cleaned with water. Easy to rust workbench, accelerate the workpiece oxidation.

2.Cleaning and maintenance of cooling system of fiber laser cutting machine

A.Check the temperature of cooling water. The recommended water temperature is below 35 degrees. General inlet of fiber laser source is 22℃≤ temperature ≤25℃. ; Prevent freezing of circulating water and freezing crack of laser tube in winter (antifreeze can be added)

B.The water in the chiller needs to be replaced regularly. Generally, the replacement frequency is one month. The specific replacement frequency depends on the actual usage. Note: Use distilled water without impurities, such as pure water or mineral water, but do not use tap water.

3.Fiber laser cutting machine other maintenance matters

A.Cleaning and maintenance of exhaust fan

When the fan suction of the fiber laser cutting machine is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the inlet and outlet air pipes , remove the dust inside, and then invert the fan, pull the inner fan blade to clean, and then install the fan.

B.Working environment requirements

The workshop where the fiber laser cutting machine is placed must be kept dry and well ventilated. The best indoor temperature is between 4-33 degrees. Prevent condensation in summer and take anti-freezing measures in winter.

Laser cutting machine should be far away from electromagnetic interference, away from high power and strong earthquake place. The interference of high power will lead to equipment failure from time to time. Take care to prevent this from happening.

C.During the running of the laser machine, observe the running status of the fiber laser frequently. In case of any abnormality, stop the operation of the fiber laser machine immediately. Cut off the power supply, and report to professional personnel to check and repair the fiber laser equipment in time. Do not disassemble or repair the fiber laser cutter without permission.

D.If for some materials, you can not determine whether the fiber laser cutting machine can be processed. Then do not process, or consult after-sales personnel in time, so as not to cause potential danger and damage to fiber laser source.

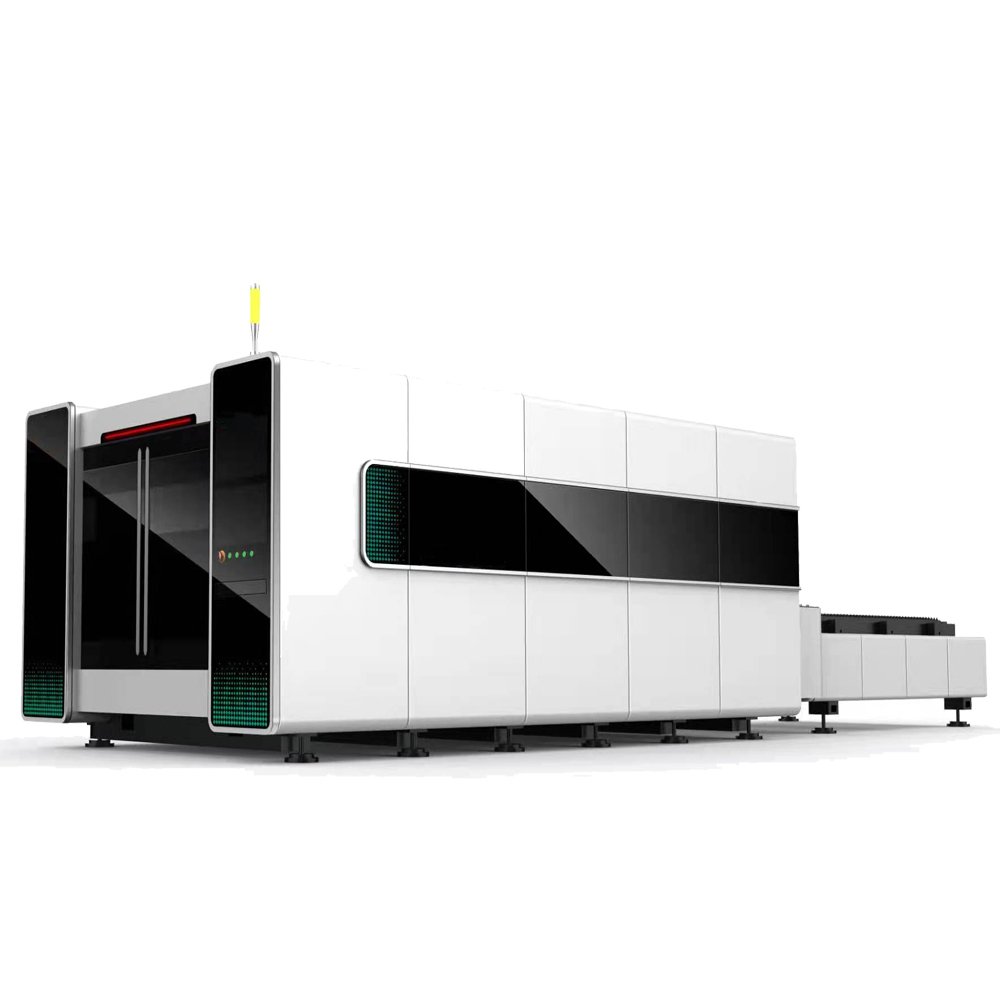

Owin laser manufacturer mainly produces fiber laser cutting machines,CO2 laser engraving and cutting machine,laser marking machines,cnc router and so on equipment.

Products are widely used for sheet metal processing,,electronics,

electrical appliances,elevators,precision parts,subway parts,automobiles,ships,metallurgical equipment,textile machinery,engineering machinery,household appliances,craft gifts,aviation,aerospace,tool processing,decoration,advertising,kitchen processing and so on processing industries.