How to set the parameters of MOPA fiber laser marking machine for anodic alumina blackening?

With the popularization and development of the application of laser processing technology, anodic alumina blackening application is gradually accepted by the market. And it is also widely used in many industrial fields. But in the practical application process, the anodic aluminum blackening process has higher requirements for laser light source, equipment accuracy, environment, operator experience, raw materials and other factors. Many customers have encountered various problems in many aspects.

- Material factors

The main factors affecting the anodic aluminum blackening are the film thickness of oxide layer and the surface treatment process.

General film thickness is between 5-20μm. Film thickness directly affects the blackening effect and efficiency. The most suitable thickness is between 10-20μm, when the film thickness is less than 8μm, the oxide film is too thin, easy to break, resulting in the phenomenon of white spots.We need to increase the pulse frequency and filling density timely.

In addition, the most common treatment process of the anodic alumina surface is sand blasting and wire drawing. The finer the particles, the better the black effect.

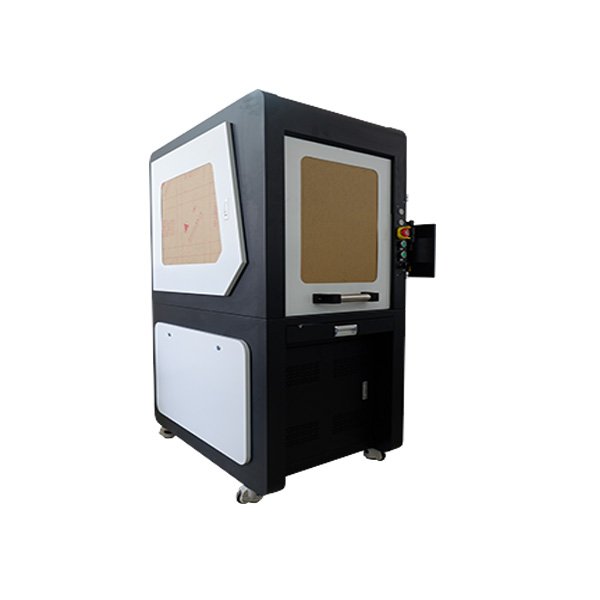

2.The installation and parameter setting of mopa fiber laser marking machine

①The installation and dimming of the laser source

When installing the laser source,we need to ensure that the power supply, control board and other components are properly connected. The galvanometer is in a horizontal position with the workpiece surface. The light axis of the laser source incident spot overlaps with the laser source incident port of the galvanometer. And the outgoing spot is located in the center of the light outlet hole.

② Power and frequency

For MOPA fiber laser marker, the main laser parameters is the power and frequency settings. The higher the frequency, the shorter the pulse width and the higher the power required.

3.The impact of marking process

The blackening process of MOPA fiber laser engraving machine mainly includes field lens focal length, spot size, filling method, defocus method, etc.

① Setting of filling density and galvanometer line speed

In general, the higher the filling density, the higher the linear velocity of the galvanometer can be. On the contrary, when the filling density is lower, the linear velocity of the galvanometer should be reduced accordingly in order to achieve the best blackening effect.

② The effect of focal plane on the blackening effect

Focus defocus can be black operation, but the use of focus more. Because when using defocus operation,if the pattern is larger, or the surface property of the material is different, it is easy to appear uneven marking phenomenon.

③ Filling method

Different filling methods have different degrees of impact on black quality and efficiency.

The most commonly used method is the serpentine filling, which has fast speed and relatively average blackening effect. In practical application, different filling methods can be selected according to the effect we need.

4.The influence of the surrounding environment on the anodic aluminum blackening

① Signal interference

Mopa fiber laser marking machine generally has data line and power line. In the installation of the two lines in space to separate and avoid signal interference.

(2) Shielding layer of data line

The data line of fiber mopa laser marking machine needs to have a shield layer. And one end of the shield layer should be grounded.

(3) Avoid environmental vibration. At the same time, all power supply grounding of fiber laser marking machine should be grounded.