What is the cause of burning phenomenon for fiber laser cutting machine in the process of metal sheet? How to avoid this problem effectively?

With the maturity and development of laser cutting technology, more and more enterprises will choose fiber laser cutting machine in China as the core processing equipment in the sheet metal processing industry. But metal laser cutting equipment will go wrong in the production.The most common problem is burning edge of sheet metal.So why is caused this problem? Can it be effectively avoided in production?

There are two main reasons for this problem:

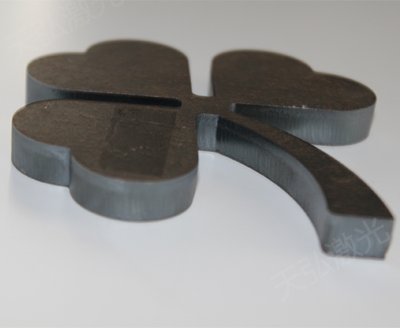

First, China fiber laser cutter will produce a lot of heat when cutting metal sheet.These heat will generally spread out along the cutting joint to achieve the effect of heat dissipation. But in the processing of small holes, the inside of the hole can be diffused within a small range,which results in heat concentration.Then it appears the phenomenon of over burning.

Second,due to the oxidation reaction caused by high temperature will accumulate molten metal and metal oxides on the surface of the workpiece in the cutting process. These substances will not only make the auxiliary airflow disorder, but also it can increase the heat input,which cases over-burning phenomenon.

The existence of over burning phenomenon greatly affects the cutting quality.So how to avoid this problem?

- When cutting a lot of workpiece with sharp corners,it often is burned the sharp corners into rounded corners due to the existence of over burning phenomenon.To avoid this problem, when affordable fiber laser machine cutting the sharp corners.Please increase the cooling time and let the auxiliary gas blow more at the sharp corners.

- When cutting carbon steel with fiber metal laser cutting machine, the auxiliary gas can be replaced with nitrogen.It can effectively avoid the oxidation reaction and avoid the oxidation layer on the cutting surface.

In addition laser cutting is completely dependent on the high temperature of the laser beam to achieve the purpose of cutting.Nitrogen itself has the role of cooling, which can effectively reduce the temperature of the cutting area. So that it can improve the cutting quality. - The pulse cutting conditions is set low frequency and peak output power, which can effectively reduce the output of heat and can effectively avoid molten metal or metal oxides accumulating in the cutting surface of the workpiece.

- Metalworking laser cutting machine is usually used nitrogen or air as an auxiliary gas in cutting aluminum alloy or stainless steel materials.Although it will not produce burning.The temperature for inside of the hole is too high,which will produce slag hanging phenomenon. If you want to avoid this problem, you can increase the pressure of the auxiliary gas.And use the gas to blow away the debris.Avoid the phenomenon of hanging slag and ensure the cutting effect.