Why is not round when fiber laser cutting machine cutting round holes?What is the reason?

In the sheet metal drilling process, the traditional way is to use the punch and relies on the external stress formed the shear force directly on the workpiece surface to complete the drilling operation. This machining method is not only low precision, but also it is easy to appear a large number of burrs at the edge of the hole wall. Then the emergence of laser cutting technology changes this situation.More and more sheet metal processing industries choose affordable fiber laser cutting machine to make round hole process. Its processing surface is smooth. The diameter of the round hole can be changed at any time. The operation is more flexible.

But in the process of use,China fiber laser cutter will meet the round hole cutting is not round, what is the reason?

- Hardware issues

Check whether the laser beam emitted by the fiber laser head is normal.Check whether the fiber laser lens is contaminated. Check whether the position of auxiliary gas nozzle and blowing direction are appropriate. Check whether the servo motor or laser head is loose. - Auxiliary gas pressure

If the auxiliary gas pressure is too small for fiber laser cutting machine in the process of working, there will be slag hanging and carbonization phenomenon at the cutting edge. If the pressure is too large,it is very easy to burst. This requires a comprehensive consideration to choose the most appropriate air pressure to cut according to the material, thickness and other conditions. - Round hole diameter

In sheet metal round hole processing, the best ratio of hole diameter and sheet metal thickness minimum is 1:1. The greater of this ratio is, the cutting efect is better. It is meaning that the larger the diameter of the round hole is, the easier it is to cut out high-quality round hole. If the ratio is lower than 1:1, it is easy to appear residual hole wall and hole not round. - Servo motor parameter setting

Sometimes, the circular hole cutting by fiber laser cutting machine is not round,which is affected on the movement of X and Y axis not match. If this happens, the direct reason is that there is a problem with the parameter adjustment of the servo motor. - Guide rail and ball screw precision error

The precision error of guide rail and ball screw is the processing error of fiber laser cutting machine, which directly depends on the production level of the fiber laser manufacturer. All industrial processing equipment has processing error basically, so we should sharpen our eyes when choosing fiber laser cutting machine price, it is necessary to choose high quality fiber laser machine.

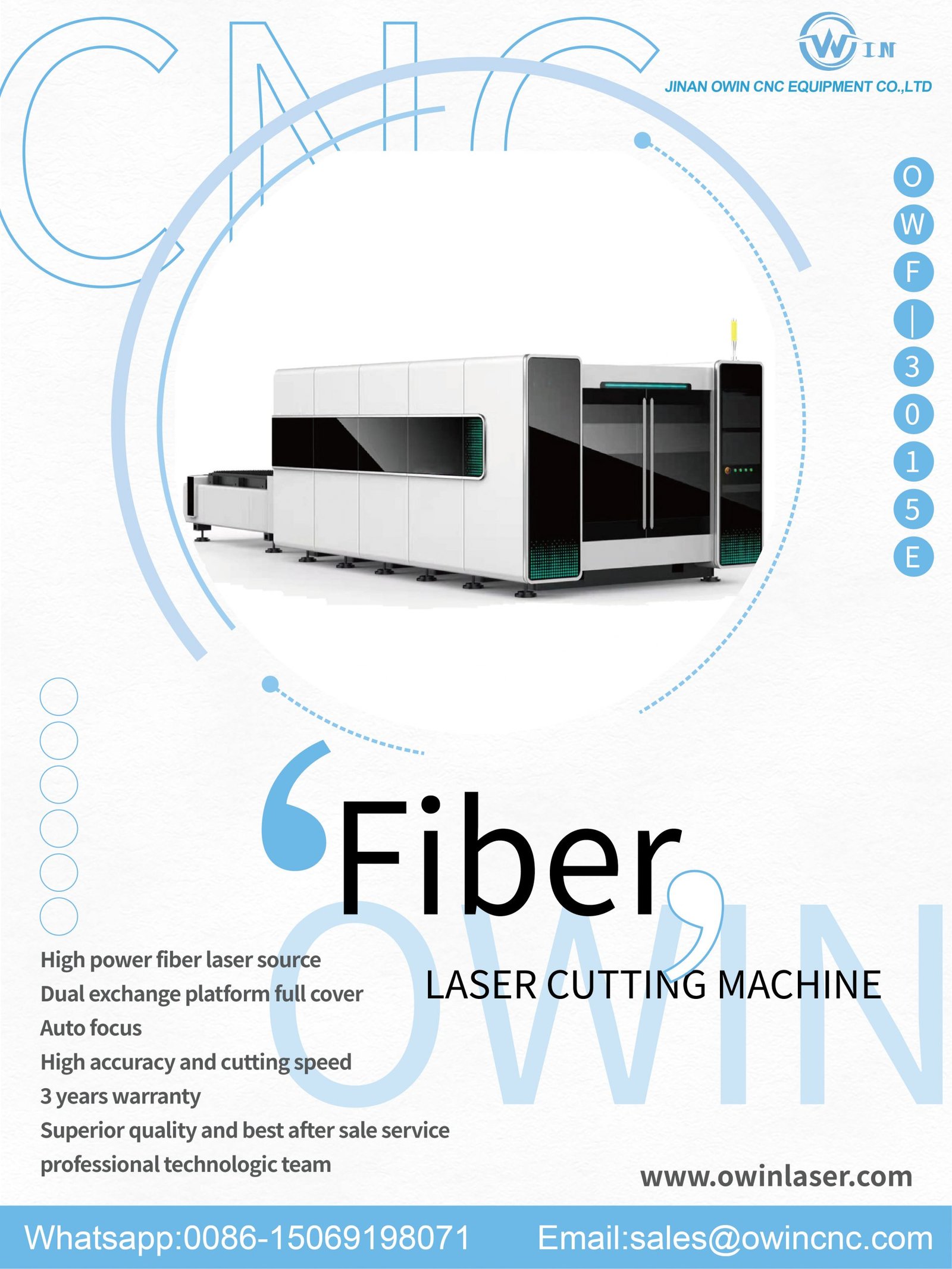

Owin fiber laser cutting machine manufacturer mainly produces fiber laser cutting machines,CO2 laser engraving and cutting machine,laser marking machines,cnc router and so on equipment.

Products are widely used for sheet metal processing,,electronics,

electrical appliances,elevators,precision parts,subway parts,automobiles,ships,metallurgical equipment,textile machinery,engineering machinery,household appliances,craft gifts,aviation,aerospace,tool processing,decoration,advertising,kitchen processing and so on processing industries.