- Home

- Product

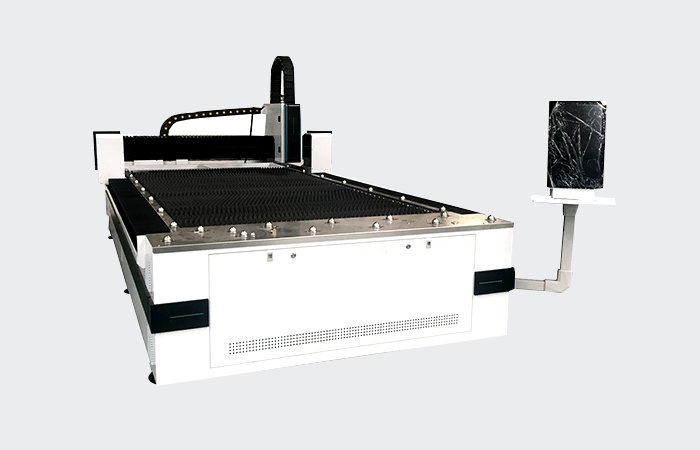

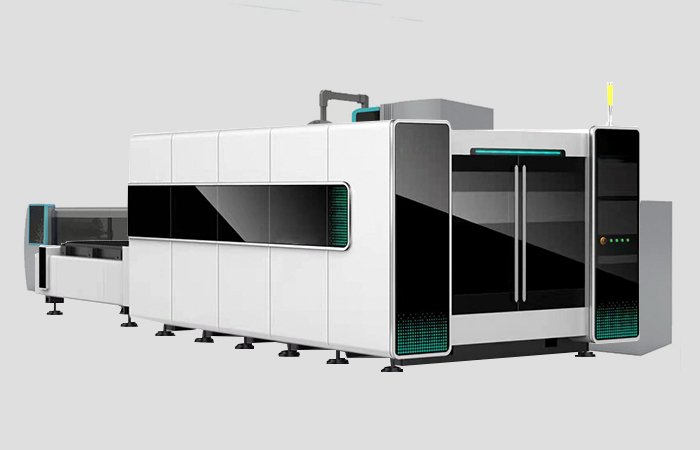

- Sheet fiber laser cutting machine

- OWF-4020H High power fiber laser cutting machine

Auto focus laser head with high quality Raycus fiber laser source,high quality laser beam, heavy duty steel plate welding machine structure,large working table 4000x2000mm size.

Equipment model | OWF-4020H |

Laser type | Fiber laser |

Laser working media | Fiber |

Laser wavelength | 1070nm |

Rated output power | 4000W |

Beam quality | <0.373mrad |

Effective cutting range | 4000*2000mm |

Workbench axial positioning accuracy | ≤±0.02mm/m |

Workbench Repositioning Accuracy | ≤±0.01mm/m |

Cutting Speed | ≤30m/min (Depends on material) |

Workbench maximum load | 3000KG |

Rated parameters of power supply | 3 Phase AC 380V 50Hz |

Equipment electric power | 10-30KW |

Total power protection class | IP54 |

Electric oil pot | Timely quantitative automatic filling |

Empty line speed | 100m/min |

Single positioned accuracy | <0.03mm |

weight | 4500KG |

High powered fiber delivered direct diode laser mainly used in hardening and cladding. In hardening applications lasers are excellent heat source for hardening of metal parts for preventing surface wear while preserving the metallurgical properties of the base material. A partial hardening can be realized while the higher flexibility of the ferritic structure can be kept in other zones as well. At induction hardening, this selective processing is not possible. As almost no warping of material is caused, there is often no need for additional methods to correct deformations of the workpiece. Laser cladding is an additive manufacturing process in which material is fused onto a substrate. The laser cladding process is often used in heavy construction industries to build a new surface for increased functionality, as well as repair damaged surfaces that worn down by repeatedly use. The laser beam creates a molten pool at the workpiece surface, to which is simultaneously added the coating material molten by the laser. The result is a layer that is connected with the basic material metallurgical. It is tougher than the coatings created by thermal spraying, and compared to hard chromium plating for example, it is harmless to health.

- Famous and best brand

- Running fast

- Stable performance

- High sensitivity

- Suitable high power

- High precision and speed

- Big torque

- Low noise

- Large scale transmission ratio

- Stable performance

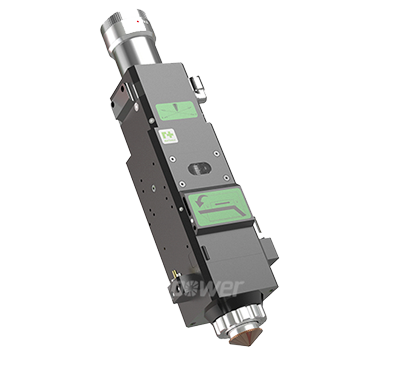

- Auto focus

- Auto adjust laser spot

- High precision cutting

- Milling by 5 axis machine to make sure high precision

- Handled by high temperature tempering

- No deformation after using three years

Jinan owin cnc equipment Co.,LTD is located in Jinan city,Shandong province. Our factory coves 6,000 square meters and own more than 100 employees including research and develop department,design department,production department,sales department,after sale service department,quality inspection department and finance department.

Owin factory is divided into 4 area,which are economic model fiber laser machines area,high power custom fiber laser cutting machines area, finished machines area and show room.

Owin laser is gradually improving according to the request and feedback from the customers.Products are more and more humanization and optimization. Hundreds of laser machine equipment are manufactured every month.Owin laser provides customers with timely and professional product analysis, design and maintenance work. Sincerely to cooperate with all of you.