What matters needing attention when cutting carbon steel by fiber laser cutting machine cutting?

Compared with other metal materials, the hardness of carbon steel is larger. So when cutting carbon steel by fiber laser cutting machine, in order to prevent laser equipment faui, to the fiber laser cutting machine inspection and maintenance into regular work.

If the cutting effect is not ideal or there are problems, it is necessary to check all aspects of affordable fiber laser cutting machine in time. Under normal conditions, the cutting effect of carbon steel should be burr-free and the traction line should be consistent.

So what problems will appear when using fiber laser cutting machine processing carbon steel material?And how to solve it?

1.Reasons for poor cutting effect

A.The focal position of the fiber laser is shifted. In this case, focus position should be tested in time and further adjusted according to the offset.

B.The laser power drops. Need to check whether the laser generator can work normally. If the laser is normal, then check whether the output value of the laser control is correct.

C.Sometimes the slow speed cutting line will affect the cutting effect.At this time it is necessary to adjust the line speed appropriately.

D.Fiber laser cutting machine auxiliary gas impure. Higher purity auxiliary gas needs to be replaced.

E.When fiber laser cutting machine for sale works continuously for a long time, the fiber laser metal cutter may run unstably. You need to shut down and restart.

F.Too fast cutting line speed is one of the important reasons leading to cutting impenetrability. It should be checked and adjusted in time.

2.Abnormal spark occurs when cutting

When cutting carbon steel by fiber laser cutting machine, the normal spark is long, flat and less fork. If the spark is abnormal, the quality of the cut section will be seriously degraded.

If the other parameters of the cutting machine are normal, the following situations should be considered.

A.Auxiliary gas nozzle loss is serious, need to be replaced in time.

B.If there is no spare nozzle to replace, the pressure of the auxiliary gas can be temporarily raised to reduce the impact.

C.The nozzle is loose. When the thread between the nozzle and the laser head becomes loose, the fiber laser cutter should be stopped immediately. The connection state should be checked.And the nozzle should be tightened again.

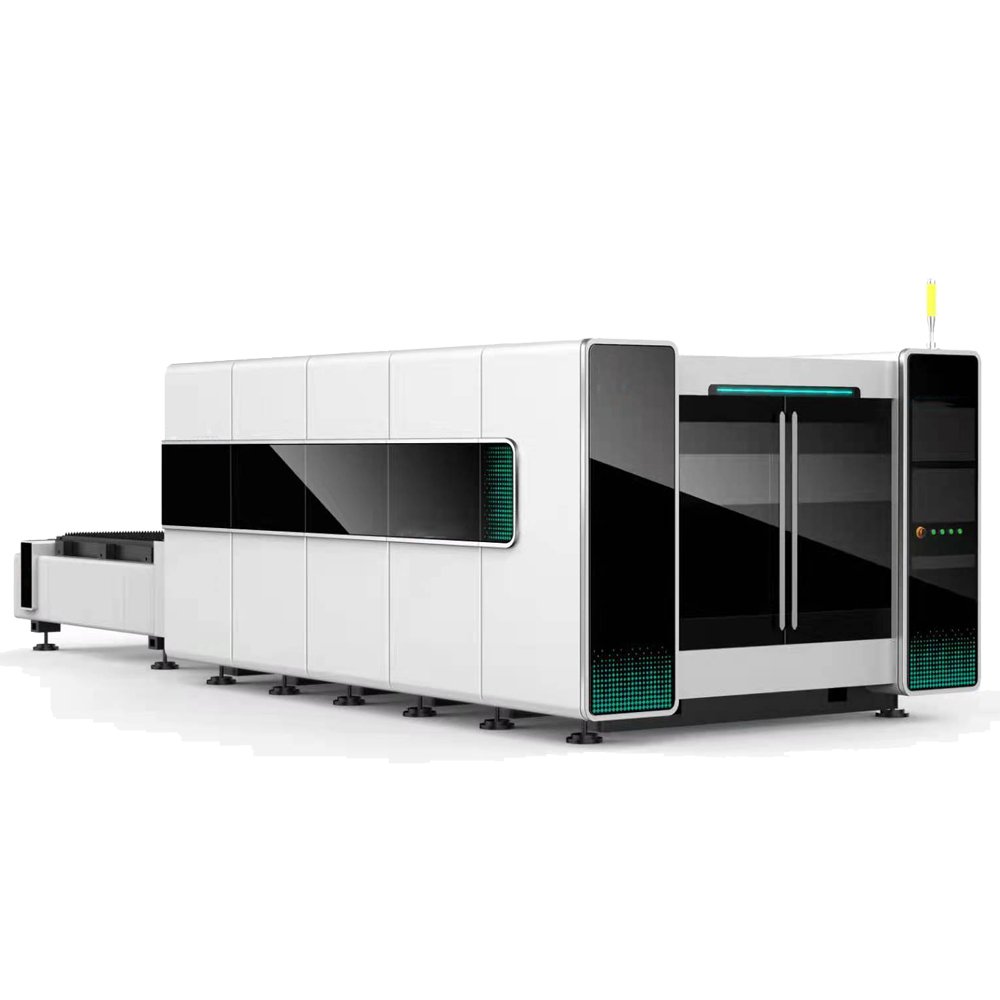

Owin fiber laser cutting machine manufacturer mainly produces fiber laser cutting machines,CO2 laser engraving and cutting machine,laser marking machines,cnc router and so on equipment.

Products are widely used for sheet metal processing,,electronics,

electrical appliances,elevators,precision parts,subway parts,automobiles,ships,metallurgical equipment,textile machinery,engineering machinery,household appliances,craft gifts,aviation,aerospace,tool processing,decoration,advertising,kitchen processing and so on processing industries.