How to correctly choose the auxiliary gas of fiber laser cutting machine?

As a general processing method in modern industrial manufacturing, fiber laser cutting machine in China is widely used in all walks of life. As we all know, the auxiliary gas must be used in the cutting process of fiber laser cutter. When cutting different materials, the auxiliary gas used is not the same. so how to choose the right auxiliary gas?

Common auxiliary gases mainly include air, nitrogen, oxygen and argon. According to different auxiliary gases, their characteristics and applicable materials are introduced below.

- Air

Air is supplied directly by the compressor. And the cost is very low compared to other auxiliary gases. The oxygen content in the air is about 20%, and about 70% is nitrogen. The cutting efficiency of the fiber laser metal cutter using air as an auxiliary gas is much lower than oxygen, similar to nitrogen. And because of the presence of oxygen, so the cutting section will occur oxidation reaction, forming a layer of oxide film, cut end face yellow.

- Nitrogen

When nitrogen is used as an auxiliary gas, no oxidation reaction will occur,which can effectively prevent the appearance of oxidation film and improve the cutting accuracy. Strong corrosion resistance, and the end cutting face is white.

Nitrogen is mainly suitable for stainless steel, plating steel, brass, aluminum, aluminum alloy and other metal materials.

- Oxygen

When oxygen is used as the auxiliary gas of affordable fiber laser cutting machine, it is mainly used to cut carbon steel. At high temperature, oxygen can generate oxidation reaction with iron and carbon of mild steel, which greatly improve the cutting efficiency. The oxide film formed by oxidation reaction can also improve the beam spectrum absorption factor of high anti-material. And the end face of the incision will be black or dark yellow.

Main application materials: carbon steel, tool board, stainless steel, copper, copper alloy, etc.

- Argon gas

Argon gas is an inert gas. As the auxiliary gas of fiber laser cutting machine, it will not oxidize or nitride with the target material, which further improves the cutting accuracy. But argon is more expensive than other auxiliary gases. The end face of the incision is white.

Main applications: Titanium, titanium alloy, etc.

In practical applications, we can see that most of the auxiliary gases can be universal,which mainly depends on the cutting cost and the requirements of the cutting effect.

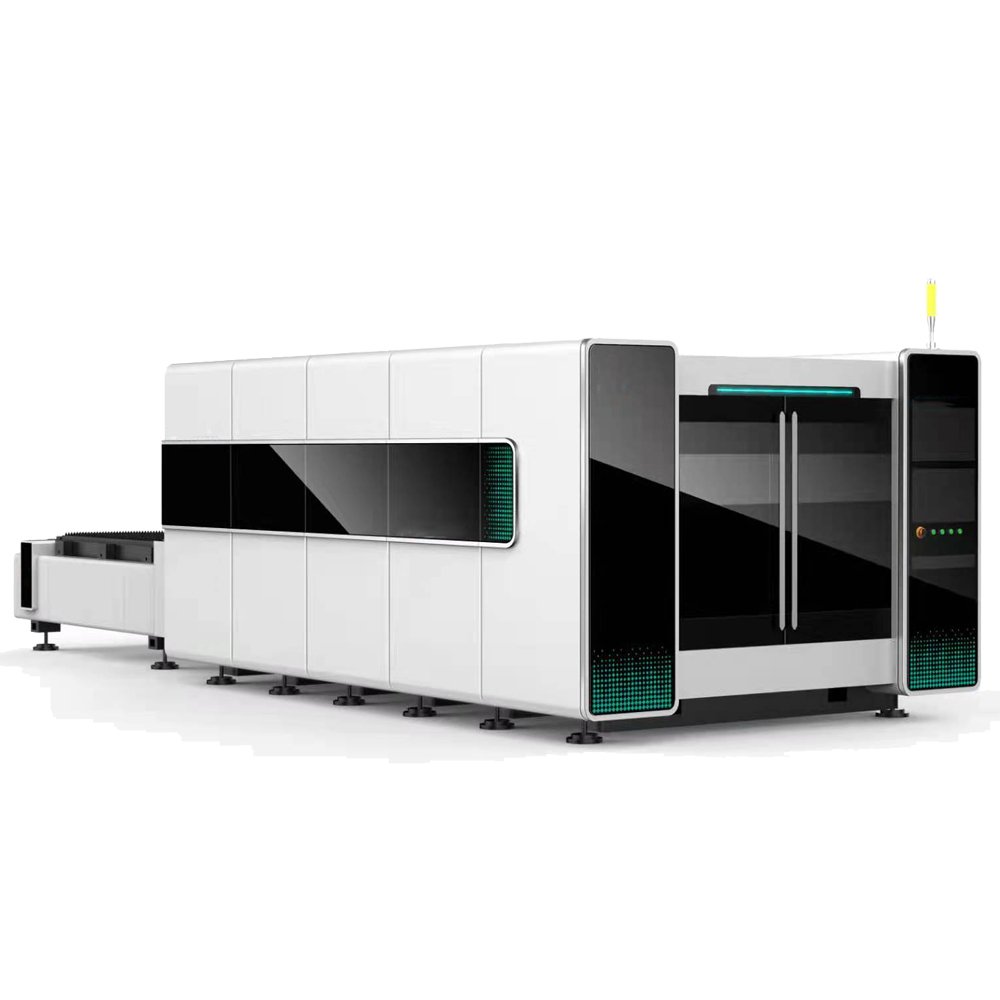

Owin fiber laser manufacturer mainly produces fiber laser cutting machines,CO2 laser engraving and cutting machine,laser marking machines,cnc router and so on equipment.

Products are widely used for sheet metal processing,,electronics,

electrical appliances,elevators,precision parts,subway parts,automobiles,ships,metallurgical equipment,textile machinery,engineering machinery,household appliances,craft gifts,aviation,aerospace,tool processing,decoration,advertising,kitchen processing and so on processing industries.